What Is HMI Software? Key Features and Industry Applications

Introduction

HMI software, or Human-Machine Interface systems, serves as a critical link between operators and machinery. This connection enables seamless interaction, significantly enhancing operational efficiency across various industries. This article explores the defining features and functionalities of HMI software, illustrating how these systems empower users to monitor and control complex processes with ease. As technology evolves rapidly, industries must adapt to leverage the latest advancements in HMI applications while ensuring both security and usability.

Define HMI Software: Core Functions and Features

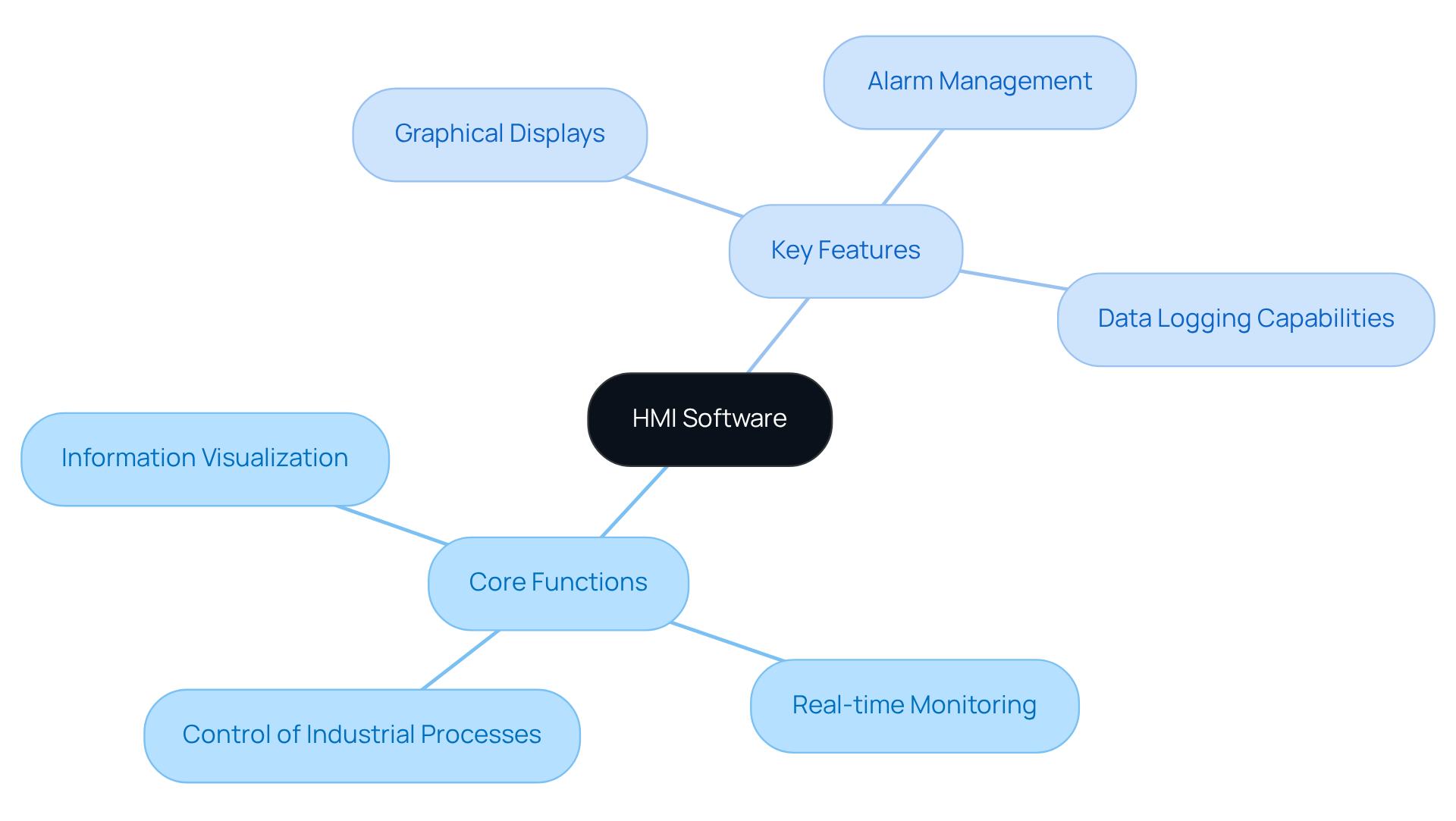

HMI applications, or Human-Machine Interface systems, are crucial for understanding what is HMI software and facilitating interaction between humans and machines. They provide an intuitive dashboard that allows operators to effectively oversee and manage machinery, systems, or devices. The core functions of HMI applications encompass information visualization, real-time monitoring, and control of industrial processes.

Key features typically include:

- Graphical displays

- Alarm management

- Data logging capabilities

All of which contribute to enhanced operational efficiency and safety. For example, in manufacturing, HMI applications empower operators to visualize production metrics and respond promptly to alarms, thereby ensuring smooth operations and facilitating quick troubleshooting.

As of 2026, the global market for what is HMI software is projected to grow from USD 6.10 billion in 2025 to USD 10.83 billion by 2032, indicating a significant demand for advanced solutions in what is HMI software. Industry authority Tray Erwin emphasizes that ‘what is HMI software is a crucial component in contemporary technology, connecting humans and machines.’

Recent innovations have introduced features such as customizable dashboards and improved data organization, enabling operators to tailor their interfaces for specific tasks. This customization enhances decision-making and operational control. Furthermore, the integration of advanced technologies, including voice recognition and augmented reality, is transforming HMI systems, making them more intuitive and accessible, which is essential for modern industrial applications.

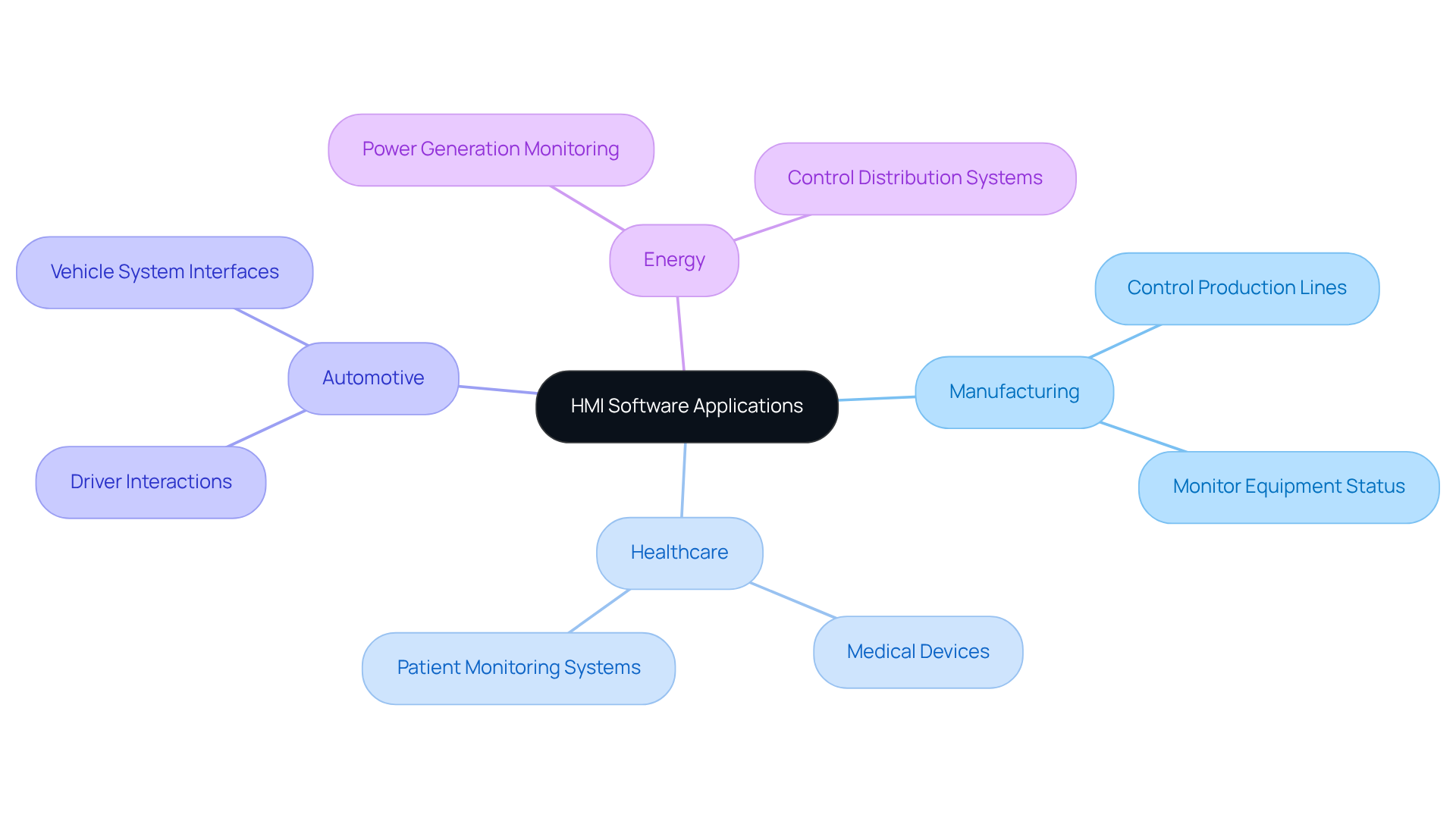

Explore Applications of HMI Software Across Industries

HMI applications are prevalent across various industries, including manufacturing, healthcare, automotive, and energy. In the manufacturing sector, these applications are employed to control production lines and monitor equipment status, thereby enhancing both productivity and safety. In healthcare, HMI applications are integrated into medical devices, enabling healthcare professionals to interact effectively with diagnostic equipment and patient monitoring systems. The automotive industry leverages HMI applications to facilitate driver interactions with vehicle systems, which improves user experience and safety. Furthermore, in the energy sector, HMI applications play a critical role in monitoring and controlling power generation and distribution systems, ensuring both reliability and efficiency.

Trace the Evolution of HMI Software: Historical Context and Development

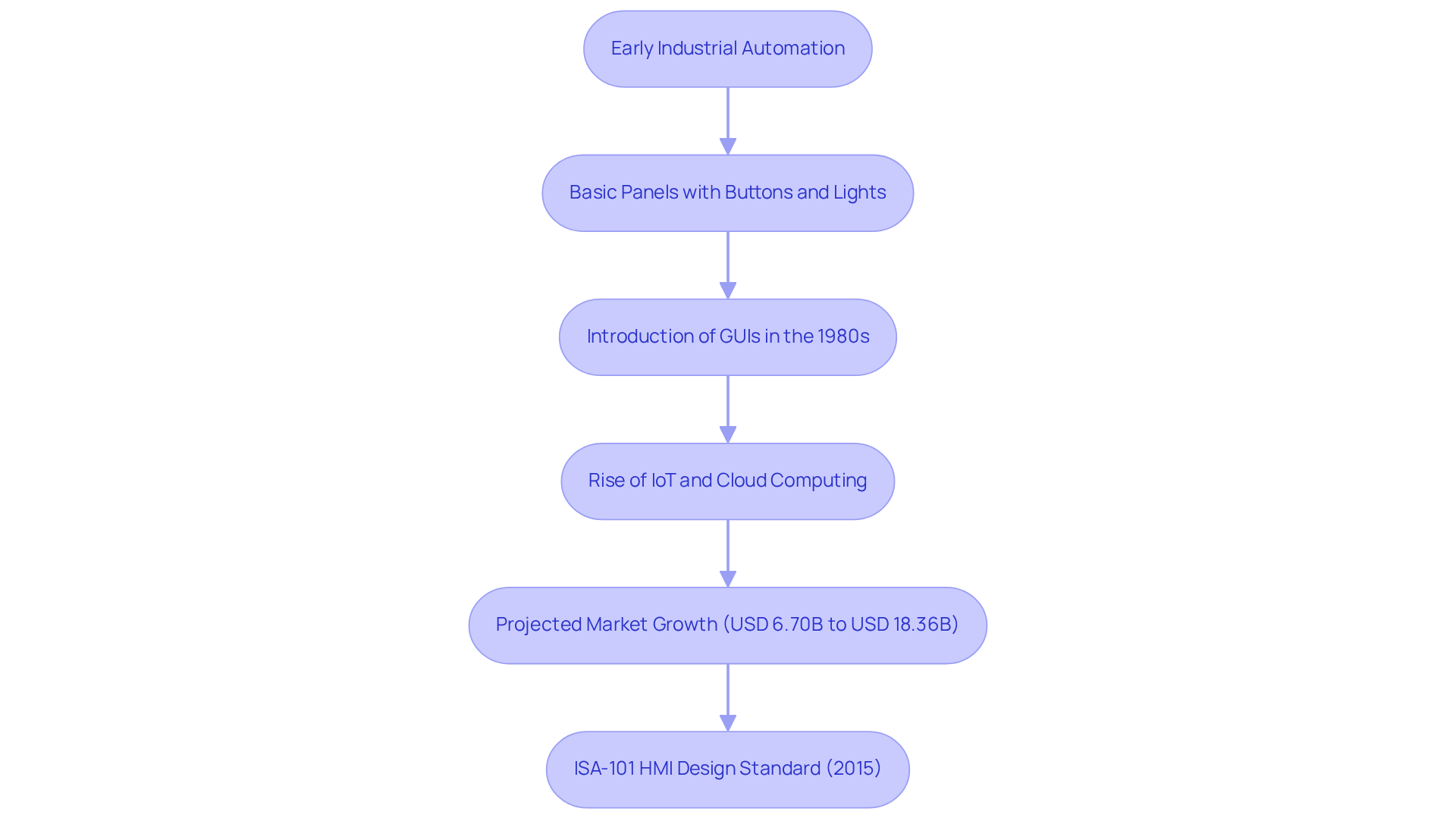

The evolution of HMI applications can be traced back to the early days of industrial automation, characterized by basic panels equipped with buttons and lights. Over the decades, technological advancements have transformed HMIs into sophisticated digital solutions capable of complex data visualization and interaction. A significant milestone occurred in the 1980s with the introduction of graphical user interfaces (GUIs), which facilitated more intuitive user interactions.

In recent years, the rise of the Internet of Things (IoT) and cloud computing has further advanced HMI applications, enabling remote monitoring and control. This capability allows operators to manage systems from virtually anywhere, thereby enhancing operational flexibility and responsiveness. The human machine interface market is projected to expand from USD 6.70 billion in 2025 to USD 18.36 billion by 2034. This growth will be driven by an increasing emphasis on advanced analytics, predictive maintenance, and the integration of augmented and virtual reality technologies, all of which will significantly influence the future of HMI applications.

Moreover, the ISA-101 HMI Design Standard, published in 2015, addresses design challenges in traditional HMIs, underscoring ongoing efforts to improve usability and effectiveness. Case studies, such as the Siemens SIMATIC WinCC Unified System, illustrate the practical applications and advantages of HMI technology in real-world scenarios, demonstrating how these advancements contribute to enhanced operational efficiency.

Identify Key Characteristics and Components of HMI Software

Key characteristics of HMI applications include user-friendliness, real-time information processing, and robust security features. The essential components consist of input/output devices, display units, and processing units. Input devices, such as touchscreens and buttons, facilitate user interaction, while display units provide visual feedback through graphs and dashboards, thereby enhancing operational awareness.

HMI applications typically integrate with programmable logic controllers (PLCs), ensuring seamless communication between operators and machinery. Security features, including user authentication and data encryption, are critical for safeguarding sensitive operational data against unauthorized access. A significant percentage of organizations recognize that effective security measures are vital for maintaining operational integrity, underscoring the necessity of prioritizing these features in HMI systems.

Real-world applications illustrate what HMI software is, showing that industries leveraging advanced components can achieve improved efficiency and safety, highlighting the transformative impact of these technologies in industrial settings.

Conclusion

HMI software acts as a crucial interface between humans and machines, significantly improving the efficiency and safety of industrial processes through intuitive interfaces. By enabling real-time monitoring, data visualization, and control, HMI applications empower operators across diverse sectors to optimize their operations and swiftly address challenges.

This article explores the fundamental functions and features of HMI software, emphasizing its importance in industries such as manufacturing, healthcare, automotive, and energy. Essential components like graphical displays, alarm management, and customizable dashboards play a vital role in enhancing productivity and ensuring safety. Moreover, the evolution of HMI technology, characterized by the integration of advanced analytics and IoT capabilities, highlights the ongoing transformation within this domain.

As industries increasingly depend on HMI applications, the necessity of investing in robust, user-friendly systems becomes evident. By adopting modern HMI solutions, organizations can not only improve operational efficiency but also foster a safer and more responsive working environment. The future of HMI software is promising, and its influence in shaping the landscape of industrial automation is undeniable.

Frequently Asked Questions

What is HMI software?

HMI software, or Human-Machine Interface systems, facilitates interaction between humans and machines, providing an intuitive dashboard for operators to oversee and manage machinery, systems, or devices.

What are the core functions of HMI applications?

The core functions of HMI applications include information visualization, real-time monitoring, and control of industrial processes.

What key features are commonly found in HMI software?

Key features of HMI software typically include graphical displays, alarm management, and data logging capabilities.

How do HMI applications contribute to operational efficiency and safety?

HMI applications enhance operational efficiency and safety by allowing operators to visualize production metrics, respond promptly to alarms, and facilitate quick troubleshooting.

What is the projected growth of the HMI software market by 2032?

The global market for HMI software is projected to grow from USD 6.10 billion in 2025 to USD 10.83 billion by 2032.

What recent innovations have been introduced in HMI software?

Recent innovations in HMI software include customizable dashboards and improved data organization, allowing operators to tailor their interfaces for specific tasks.

How are advanced technologies impacting HMI systems?

Advanced technologies such as voice recognition and augmented reality are transforming HMI systems, making them more intuitive and accessible for modern industrial applications.