Master Manufacturing Analytics Software: Best Practices for Success

Introduction

Manufacturers today face an overwhelming influx of data, yet many find it challenging to leverage this information effectively. Manufacturing analytics software stands out as a pivotal solution, equipping organizations with the necessary tools to convert raw data into actionable insights. These insights can significantly streamline operations and boost profitability. However, the path to successful implementation is not without its hurdles.

How can organizations ensure they not only adopt these tools but also fully realize their potential? This article explores best practices for mastering manufacturing analytics, offering a comprehensive roadmap for businesses eager to excel in an increasingly data-driven environment.

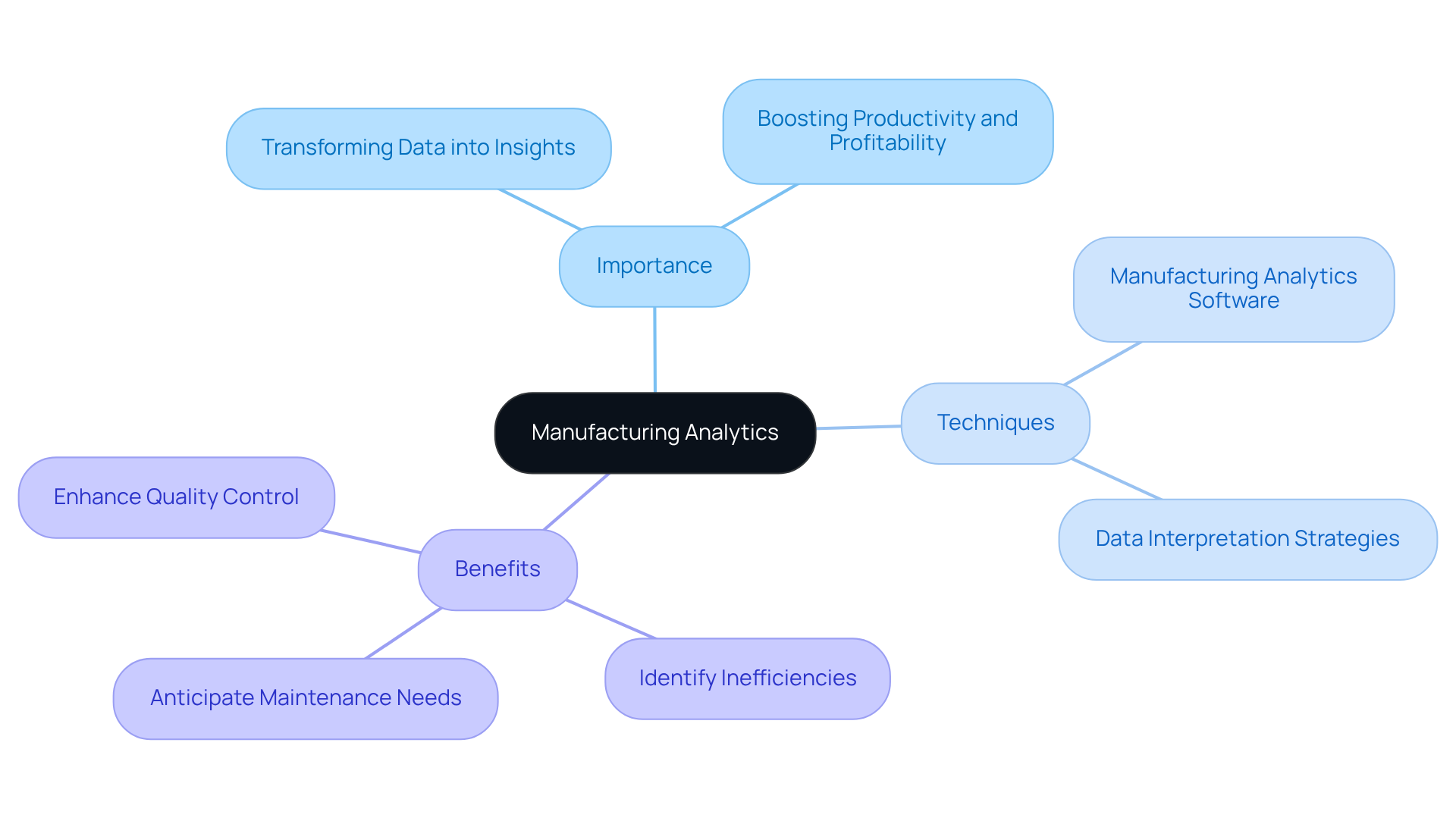

Define Manufacturing Analytics and Its Importance

Production analysis involves the systematic collection, examination, and interpretation of data generated during production processes. This practice employs various techniques and tools, such as manufacturing analytics software, that empower manufacturers to gain valuable insights into their operations, optimize production, and improve overall efficiency.

The importance of production analysis lies in its ability to transform raw data into actionable insights, allowing companies to make informed decisions that boost productivity and profitability. By leveraging manufacturing analytics software, manufacturers can:

- Identify inefficiencies

- Anticipate maintenance needs

- Enhance quality control

Ultimately, this secures a competitive edge in the marketplace.

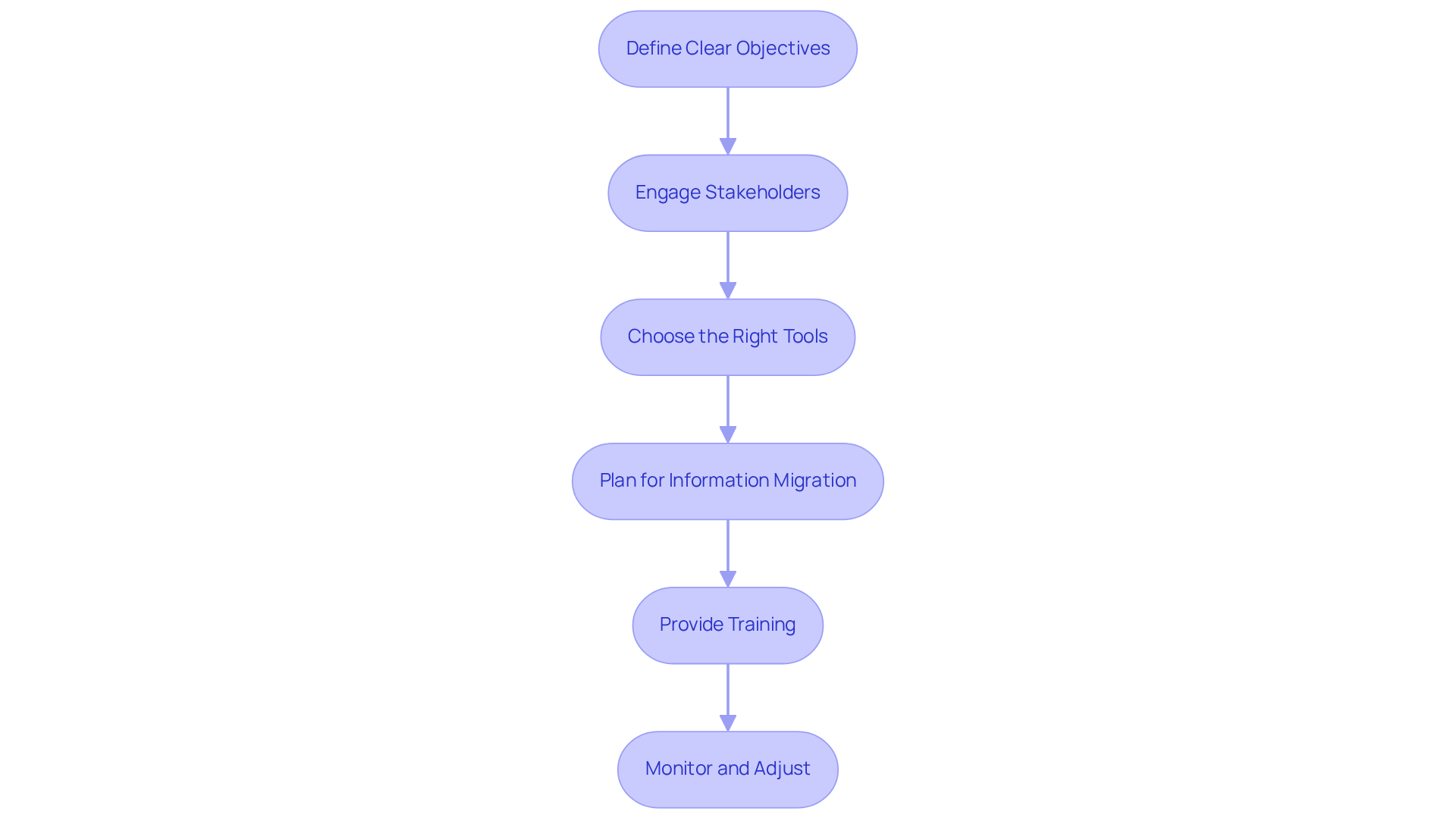

Adopt Best Practices for Software Implementation

To successfully implement manufacturing analytics software, organizations should adhere to the following best practices:

-

Define Clear Objectives: Establish specific goals for your data initiative, such as reducing downtime, enhancing product quality, or streamlining supply chain processes. Organizations that set clear goals are more likely to achieve successful results, as these objectives provide focused direction for data analysis efforts. Elizabeth Payes emphasizes that defining clear objectives is crucial for maximizing the potential of smart manufacturing.

-

Engage Stakeholders: Involve key stakeholders from various departments early in the process. This collaboration ensures that the data analysis solution meets the diverse requirements of all users, fostering a sense of ownership and commitment to the project. Engaging stakeholders can also help prevent common pitfalls, such as misalignment between the objectives of manufacturing analytics software and business needs.

-

Choose the Right Tools: Select measurement tools that align with your defined objectives and integrate seamlessly with existing systems. Consider factors such as scalability, user-friendliness, and the level of support provided by the vendor to ensure long-term success. Industry reports indicate that the right tools can significantly enhance operational efficiency.

-

Plan for Information Migration: Develop a comprehensive strategy for transferring existing information into the new system. This plan should prioritize information integrity and compatibility, as accurate data is essential for effective analysis. Statistics show that organizations investing in robust data foundations are better positioned to adapt to market volatility.

-

Provide Training: Offer thorough training sessions for users to familiarize them with the new tools and processes. This investment in training improves user adoption and maximizes the efficiency of the data analysis solution. Training is particularly essential as the manufacturing workforce evolves due to a shortage of skilled labor.

-

Monitor and Adjust: After implementation, continuously monitor the system’s performance. Be prepared to make adjustments as necessary to enhance efficiency, ensuring that the data solution remains aligned with changing business requirements. Consistent oversight can help firms avoid the pitfalls of stagnant evaluation strategies.

In summary, establishing clear goals not only directs the execution process but also enables organizations to utilize data effectively, leading to improved decision-making and operational enhancements.

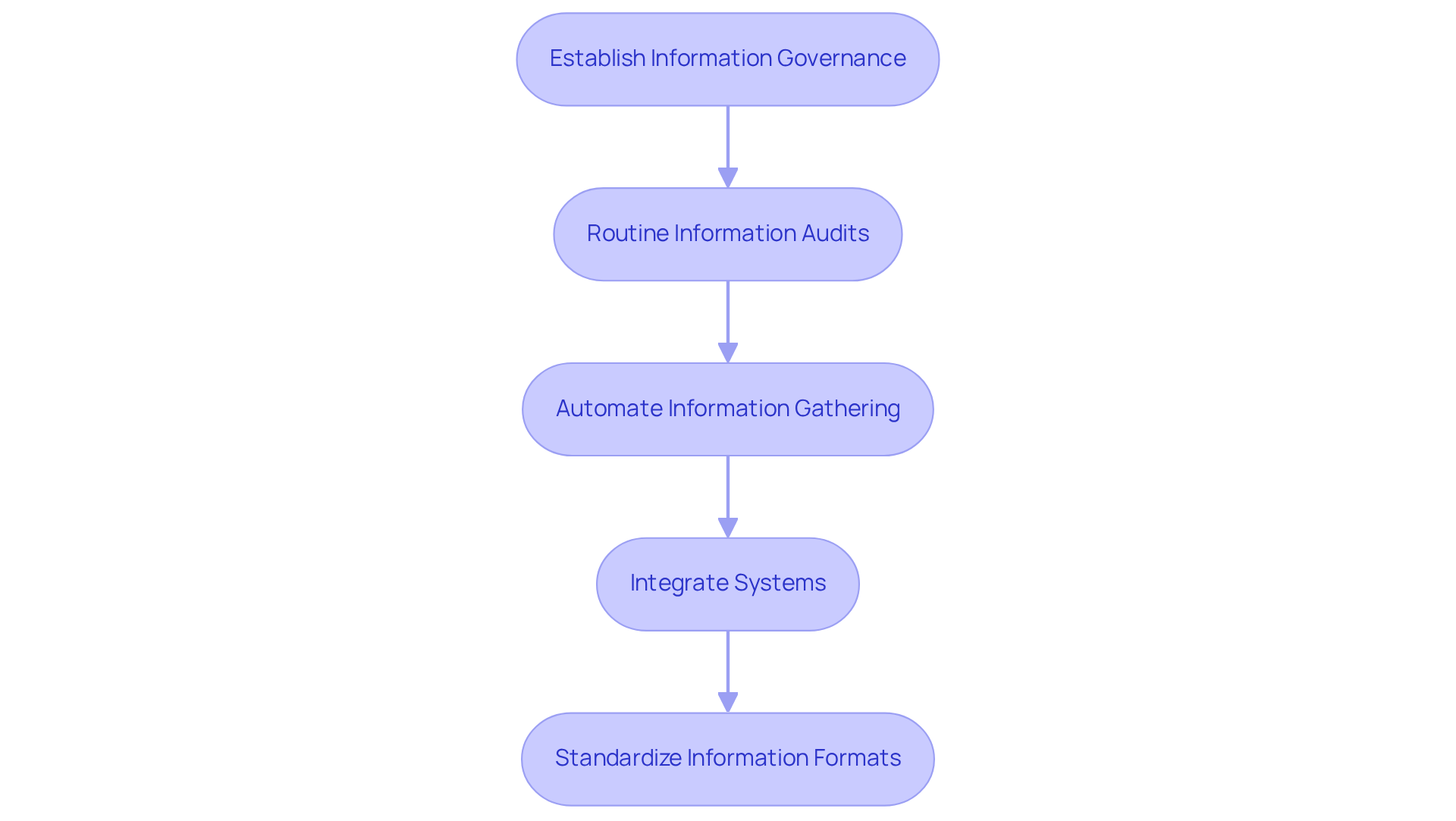

Ensure Data Quality and Integration for Effective Analytics

To achieve effective manufacturing analytics software, organizations must prioritize the quality and integration of information. The following strategies are essential:

- Establish Information Governance: Implement a robust information governance framework that clearly defines ownership, quality standards, and compliance requirements.

- Routine Information Audits: Conduct regular audits of information sources to identify and rectify inaccuracies or inconsistencies. This practice is vital for maintaining high information quality over time.

- Automate Information Gathering: Utilize automated information collection techniques to minimize human errors and ensure real-time accessibility of information. This may involve the use of IoT devices and sensors on the production floor.

- Integrate Systems: Ensure that all relevant systems, such as ERP, MES, and quality management systems, are interconnected to provide a cohesive view of information across the organization.

- Standardize Information Formats: Adopt standardized information formats to facilitate smoother integration and analysis. This approach reduces the complexity of data handling and enhances compatibility between systems by utilizing manufacturing analytics software.

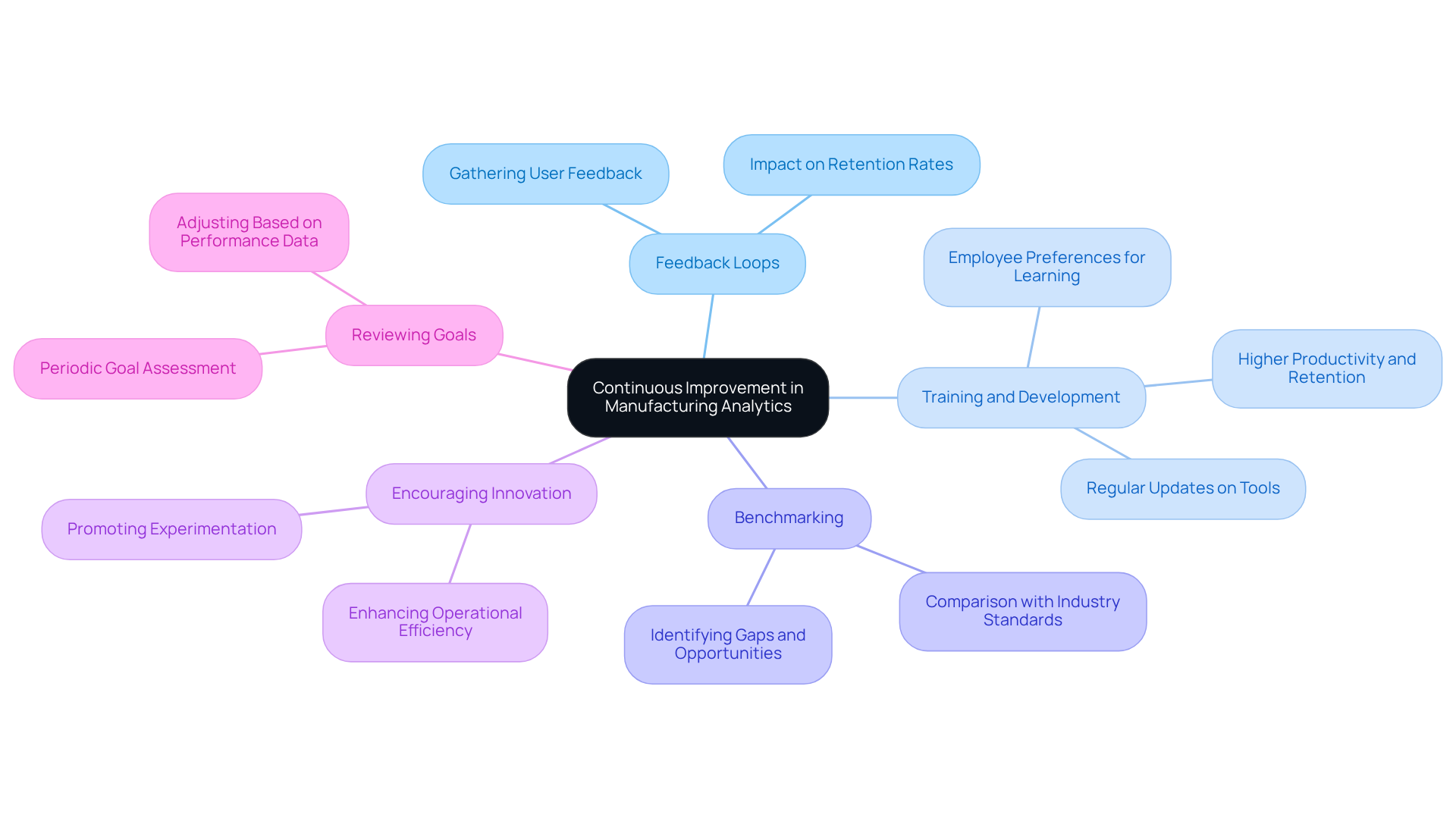

Embrace Continuous Improvement and Adaptation

To cultivate a culture of continuous improvement in manufacturing analytics, organizations should adopt several key strategies:

-

Implement Feedback Loops: Establish robust mechanisms for gathering feedback from users and stakeholders. This practice is essential for identifying areas needing enhancement in data processes, fostering a responsive environment where insights can lead to actionable improvements. Listening to employee feedback can significantly impact retention rates, reinforcing the importance of these mechanisms.

-

Invest in Training and Development: Regularly refresh training programs to include the latest data analysis tools and methodologies. Research indicates that companies with comprehensive training programs experience significantly higher productivity and employee retention. Notably, 68% of employees prefer to learn or train in the workplace, making it crucial to ensure staff are well-versed in current technologies to maintain a competitive edge.

-

Benchmark Against Industry Standards: Consistently compare your data analysis practices with industry best practices. This benchmarking process, supported by manufacturing analytics software, helps identify gaps and opportunities for enhancement, enabling organizations to stay aligned with evolving market demands and technological advancements.

-

Encourage Innovation: Foster an environment that promotes experimentation and creativity in data analysis methods. Encouraging teams to explore new technologies and methodologies can lead to breakthroughs that enhance operational efficiency and data-driven decision-making.

-

Review and Revise Goals: Periodically reassess organizational goals related to manufacturing data analysis. Adjust these goals based on performance data and market changes to ensure they remain relevant and achievable, thereby driving continuous improvement in analytics outcomes.

Conclusion

Mastering manufacturing analytics software is crucial for organizations seeking to optimize production processes and maintain a competitive edge. By effectively harnessing data, manufacturers can convert insights into actionable strategies that enhance efficiency and profitability. The successful implementation of manufacturing analytics relies on clear objectives, stakeholder engagement, and the appropriate tools, enabling companies to navigate the complexities of modern manufacturing landscapes.

Key arguments underscore the significance of data quality and integration, along with the necessity for continuous improvement. Establishing robust information governance, conducting routine audits, and fostering an environment that promotes innovation are essential components of a successful analytics strategy. Furthermore, investing in training and adjusting goals based on performance data allows organizations to remain responsive to market changes and technological advancements.

Ultimately, embracing manufacturing analytics transcends merely adopting new software; it involves cultivating a culture of data-driven decision-making that encourages continuous growth and adaptation. Organizations should view analytics as an ongoing journey, where feedback and innovation are pivotal in achieving sustained success within an ever-evolving industry landscape. By prioritizing best practices and committing to improvement, manufacturers can fully realize the potential of their analytics initiatives.

Frequently Asked Questions

What is manufacturing analytics?

Manufacturing analytics is the systematic collection, examination, and interpretation of data generated during production processes, utilizing various techniques and tools to gain insights into operations.

Why is manufacturing analytics important?

It is important because it transforms raw data into actionable insights, enabling companies to make informed decisions that enhance productivity and profitability.

What are some benefits of using manufacturing analytics software?

Benefits include identifying inefficiencies, anticipating maintenance needs, and enhancing quality control.

How does manufacturing analytics contribute to a company’s competitiveness?

By leveraging insights from data analysis, manufacturing analytics helps companies optimize production and improve overall efficiency, securing a competitive edge in the marketplace.